Sehen Sie, wie die Multiphysik-Simulation in Forschung und Entwicklung eingesetzt wird

Ingenieure, Forscher und Wissenschaftler aus allen Branchen nutzen die Multiphysik-Simulation, um innovative Produktdesigns und -prozesse zu erforschen und zu entwickeln. Lassen Sie sich von Fachbeiträgen und Vorträgen inspirieren, die sie auf der COMSOL Conference präsentiert haben. Durchsuchen Sie die untenstehende Auswahl, verwenden Sie die Schnellsuche, um eine bestimmte Präsentation zu finden, oder filtern Sie nach einem bestimmten Anwendungsbereich.

Sehen Sie sich die Kollektion für die COMSOL Conference 2024 an

The initiation in numerical modeling of welding with COMSOL Multiphysics® is proposed to the 2nd year students of the professional master program «Processes, Controls, Metallic Materials: Nuclear Industry» (PC2M) of University of Burgundy, France since 2016 within the module «Simulation ... Mehr lesen

For a better understanding of phenomena associated to the appearance of defects in laser welding, a heat and fluid flow model is developed. This study is focused on the modeling of a static laser shot on a sample of steel. This 2D axialsymmetric configuration is used to study phenomena ... Mehr lesen

Improved performance of aeroengines requires the development of new manufacturing technologies for ceramic matrix composites (CMCs). This has been simulated using COMSOL Multiphysics. Specialized simulation technologies have been developed to describe the infiltration of molten material ... Mehr lesen

Acoustic streaming (AS) describes a physical phenomenon where an oscillating sound emitter induces a steady fluid motion. Metal processing industry applies this treatment for grain morphology adjustments during the solidification of metal. Improvement and further development of this ... Mehr lesen

The Finite Element Method (FEM) has become an established numerical tool used for different academic and industrial purposes. It allows the prediction of weld pool geometry, thermal cycle, final distortion and residual stress field during and after fusion welding. The capability of the ... Mehr lesen

The application of an oscillating magnetic field on the high-power full-penetration laser beam welding process of a 20 mm thick stainless steel plate was numerically and experimentally investigated. In the simulations, three-dimensional heat transfer and fluid dynamics as well as ... Mehr lesen

Electrical Discharge Machining (EDM) is a non-conventional process used for machining electrically conducting materials. In die sink-EDM, sparks are generated between tool and workpiece resulting in heating of both electrode surfaces and creating a melt pool of metal which leads to ... Mehr lesen

The aim of this article is to demonstrate the capability of the software for predicting free-surface motion and internal fluid flow in an electromagnetically levitated sample of liquid metal. Multiphysics solutions which demonstrate the usefulness of Comsol as a powerful MHD simulation ... Mehr lesen

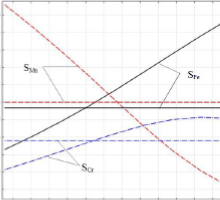

A 2D transient heat conduction model was created in COMSOL Multiphysics to simulate temperature changes in material irradiated by a KrF laser beam confined on silicon’s surface. In this paper, the obtained results are shown and discussed in case of bulk Silicon. The heat source is ... Mehr lesen

In this paper describes an original method for indirect measurement of the vapor pressure and temperature in the keyhole in electron beam welding. This method is based on the determination of the concentration of chemical elements in the vapor above the welding zone. Taking into account ... Mehr lesen