Sehen Sie, wie die Multiphysik-Simulation in Forschung und Entwicklung eingesetzt wird

Ingenieure, Forscher und Wissenschaftler aus allen Branchen nutzen die Multiphysik-Simulation, um innovative Produktdesigns und -prozesse zu erforschen und zu entwickeln. Lassen Sie sich von Fachbeiträgen und Vorträgen inspirieren, die sie auf der COMSOL Conference präsentiert haben. Durchsuchen Sie die untenstehende Auswahl, verwenden Sie die Schnellsuche, um eine bestimmte Präsentation zu finden, oder filtern Sie nach einem bestimmten Anwendungsbereich.

Sehen Sie sich die Kollektion für die COMSOL Conference 2024 an

Materials such as aluminium with high thermal and electrical conductivities are of industrial interest, particularly for the automotive industry in the current context of increasing production of electric vehicles. The reflective properties of this material make it difficult to process ... Mehr lesen

Laser technologies such as welding, cutting and metal deposition are widely used in the industry. High quality requirements regarding process products cause that there is often a need to monitor the process. For this purpose, optical sensors integrated with a laser head are often used. ... Mehr lesen

In this paper, a numerical study is conducted on the melting and solidification process of metal foam/paraffin wax with cyclic heating and cooling. A mathematical model based on the Brinkman-Frochheimer extended Darcy equation and the local thermal non-equilibrium model (LTNE) is ... Mehr lesen

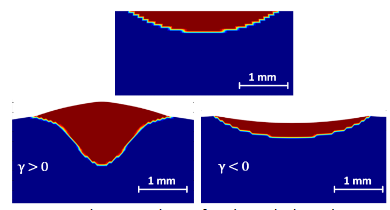

Laser cladding is an additive manufacturing process, where a laser beam creates a melt pool, into which powder is fed from a powder nozzle. Due to the feed motion of the laser beam and the powder nozzle relative to the workpiece, coatings and 3D parts can be deposited, which consist of ... Mehr lesen

Present work is done in the framework of the SisAl Pilot EU project, which aims at optimising the silicon production in Europe by recycling materials and using a carbon-emission friendly technology. The silicon production experiments are conducted on laboratory and pilot scales in ... Mehr lesen

Laser cutting process is usually employed in machining process, however it is also applied for dismantling nuclear facilities. Contrary to mechanical processes where tools wear out quickly and are often renewed, laser cutting process is a contactless approach, therefore there is no ... Mehr lesen

Additive manufacturing processes are increasingly used for designing metallic parts with complex geometries. The current needs are focused on the manufacturing of large-scale parts, typically of meter range. However, for such dimensions, the traditional trial-and-error methodology used ... Mehr lesen

Sodium/metal chloride storage batteries, used in hybrid propulsion applications, provide high energy and power densities safely and reliably. To understand the dynamics of electrochemical cycling, a high-temperature sodium/ferrous chloride storage cell was modeled in two dimensions. The ... Mehr lesen

In this paper, we present a study of the simulation of Directed Energy Deposition (DED) Additive Manufacturing (AM) using a multiphysics approach. We use a combination of Heat Transfer in Fluids, Solid Mechanics and Laminar Flow physics to accurately simulate the DED process. The ... Mehr lesen

The process-induced deformation in the DED fabricated part is a critical issue to the scaling of the technology. Currently, an inefficient and expensive experiment trial-and-error approach is utilized to tackle this issue, however it is not feasible for large parts. Researchers have ... Mehr lesen