Sehen Sie, wie die Multiphysik-Simulation in Forschung und Entwicklung eingesetzt wird

Ingenieure, Forscher und Wissenschaftler aus allen Branchen nutzen die Multiphysik-Simulation, um innovative Produktdesigns und -prozesse zu erforschen und zu entwickeln. Lassen Sie sich von Fachbeiträgen und Vorträgen inspirieren, die sie auf der COMSOL Conference präsentiert haben. Durchsuchen Sie die untenstehende Auswahl, verwenden Sie die Schnellsuche, um eine bestimmte Präsentation zu finden, oder filtern Sie nach einem bestimmten Anwendungsbereich.

Sehen Sie sich die Kollektion für die COMSOL Conference 2024 an

The present work introduces a new methodology, based on COMSOL Multiphysics® Application Builder, to account for the “beam trapping” effect in multiphysical modelling of laser welding. Incident intensities involved in laser welding processes are high enough to induce material ... Mehr lesen

The heat and fluid flow calculation inside the melt pool in welding processes is a complex challenge. It can be useful to predict defects in the weld seam or to study the influence of some process parameters. Even if the required equations are mastered over the last few years, the cost ... Mehr lesen

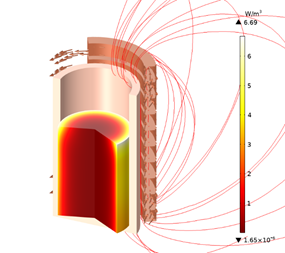

In order to improve the design of an induction furnace and to optimize the charge melting, a COMSOL Multiphysics® application is developed. This application runs a furnace model. The inductor, supplied with an alternative electrical tension, creates a variable induction field B ⃗. Due to ... Mehr lesen

This paper presents a 3D numerical model to predict the whole process of coaxial powder flow, including the particle stream flow in and below the nozzle and also the laser-particle interaction process. The Particle Tracing Module of COMSOL Multiphysics is used to solve the coupled ... Mehr lesen

Kennedy Space Center is leading research work on lunar O2 generation via electrolytic reduction of regolith. The metal oxide present in regolith is dissociated into oxygen anions and metal cations leading to the generation of gaseous oxygen at the anode and liquid metal at the cathode. ... Mehr lesen

Manufacturing of metal component in industry involves many kind of processes where materials experience high temperature and changes of state. Then, oxidation may become a significant topic regarding industrial requirement and specification. This issue is well-known in welding ... Mehr lesen

Many materials require functionally graded cellular microstructures whose porosity is engineered to meet specific requirements of diverse applications. It has been shown in previous work that the bubble growth rate of a polymeric foam can be influenced by the surrounding acoustic ... Mehr lesen

Pyrometallurgical furnaces are used to produce metals such as copper, nickel and platinum by the smelting process. During smelting, the undesired material components are separated from the desired metal resulting in the formation of a slag and matte/metal phase. The slag phase ... Mehr lesen

Laser-based powder bed fusion (LPBF) is a promising additive manufacturing technology, where metallic parts are produced in a layer-wise manner. At each step, a rapid-moving laser irradiates and subsequently melts predefined zones of a relatively thin layer of fine spherical metal ... Mehr lesen

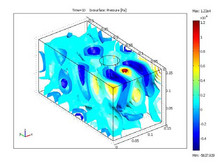

Aluminum production potlines operate under significant amperage in a range of 200 kA – 600 kA. High electrical DC currents induce strong magnetic fields. MHD stability, which is a result of electrical current and magnetic field interaction within aluminum reduction cell, is one of highly ... Mehr lesen