Comprehensive analysis of the transport phenomena developing inside a pasta drying chamber

In the sphere of pasta drying, where accurate prediction of temperature and moisture distribution is crucial, the application of modeling and simulation emerges as highly significant. This work focuses on the development of a physical-mathematical model capable of estimating the space-time evolution of the variables of interest within a pasta sample which is exposed to a stream of drying air flowing under turbulent conditions. The aim of the study is therefore to determine the best operating conditions in order to obtain a high quality product that is completely safe for human health, while at the same time trying to minimize the considerable energy consumption that typically characterizes drying processes from an industrial point of view. To generate a powerful tool capable to outline the behavior of real driers under a wide range of process conditions, the use of the transport coefficients of matter and heat at the interface between the samples to be dried and the drying medium has been disregarded, so that an advanced two-domain model was devised and solved to estimate transport phenomena in both the food and air domains (“Transport phenomena in pasta drying: a dough-air double domain advanced modeling”, Adduci et al., 2024). Therefore, the two domains have been appropriately coupled by a set of boundary conditions based on the existence of the continuity of temperature at the interface between the two phases, as well as of energy and mass fluxes; the heat and water transfer equations were solved by discretizing the two domains (food and air) using the finite element method and then numerically computed by employing COMSOL Multiphysics. Considering that the phenomena associated with phase transition lead to a very abrupt change in the physical properties of the food matrix, with consequent modification in the internal molecular mobility, implementing these phenomena is crucial to achieve the desired estimation of the final product properties ('Application of Glass Transition in Food Processing', Balasubramanian et al., 2016). Moreover, given that the effect of food shrinkage during drying have a significant impact on process performance, so that its control would lead to a significant improvement in the final quality of the dried product, a structural analysis of the samples was carried out to further improve the predictive capabilities of the model.

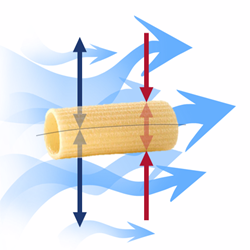

To compare results, numerical simulations were carried out on different geometries by parameterizing the initial conditions to typical values for industrial processes and assuming the extruded pasta to be dried as a poorly porous medium (“Drying of Durum Wheat Pasta and Enriched Pasta: A Review of Modeling Approaches”, Mercier et al., 2016). Accordingly, the transfer of water headed from the food core of the samples to its interface propagates exclusively in the liquid phase (“Modeling of internal moisture transport during durum wheat pasta drying”, Mercier et al., 2013).

To validate the prediction model, a drying chamber was adopted in the R&D laboratory of Barilla S.p.A, resulting in very good agreement between the experimental data and the model predictions, as can be seen inside Fig. 1.

Herunterladen

- manoli_9771_poster.pdf - 0.54MB

- 3_gaetano_adduci.pdf - 1.44MB