Structure design and optimization of lithium ion batteries tab based on thermal analysis

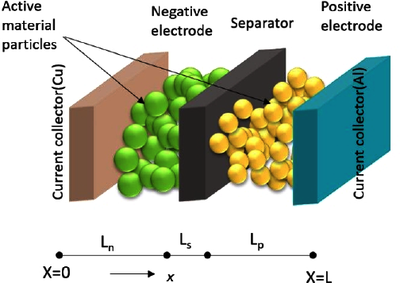

In recent years, fire and explosion accidents of mobile phones and electric vehicles are very common. If the heat generated by the battery cannot be dissipated in time will cause the battery temperature rise, or even thermal runaway. Therefore, it is necessary to decrease the heat generation rate and increase the heat dissipation rate by changing the internal structure design of the battery, such as changing the dimension of the tab as well as the dimension and number of layers of the electrode plate. The electrochemical and thermal performance of battery are analyzed using Batteries & Fuel Cells Module and Heat Transfer Module of the COMSOL Multiphysics® software. Firstly, a coupling model of 1D electrochemical model and 3D thermal model was established. The dimension of tab was optimized by studying the thermal behavior of lithium ion batteries at different discharge rates and tab dimensions. Then, a 3D multi-layer electrochemical-thermal coupling model was established to explore the influence of the dimension and number of layers of the electrode plate on the heat accumulation of the battery, so that the electrode plate can be optimized .The results show that increasing the thickness and width of the tab can effectively reduce the temperature of the battery and make the temperature distribution inside the battery more uniform. Figure 1 depicts the battery temperature distribution at the optimal tab design and 5C discharge rate, which shows a relatively uniform temperature distribution on the battery surface. With the increase of the dimension and number of layers of the electrode plate, the heat dissipation of the battery is hindered, resulting in uneven temperature distribution in the battery.

Herunterladen

- 梅_presentation.pdf - 2.5MB

- 梅_abstract.pdf - 0.03MB