Microwave Assisted Vacuum Drying Processing: Magnetron vs Solid State. Case Study: Apple Drying

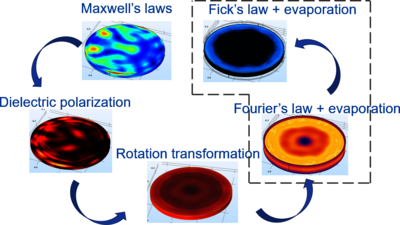

Lyophilization is a food preservation process that allows to inhibit the growth of bacteria and other contaminants by removing water content in the processed food. Conventional vacuum dryers provide heat by thermal conduction to assist the phase change transformation, but if the product is characterized by low thermal conductivity or if it is very sensitive to temperature, energy transfer rate can be strongly affected. Providing energy by microwave sources, it is possible to improve the energy transfer thanks to a direct conversion of electromagnetic energy into the material, avoiding the need for a high temperature medium. The purpose of the current study is to simulate the physical behavior with COMSOL Multiphysics® in terms of electromagnetic distribution, temperature and moisture content during the process, comparing a classical magnetron source, a one port solid state source and a two ports solid state source. The model is characterized by a vacuum chamber, a turntable, a waveguide (or two in the case of 2 ports system) and food product. The simulated physics includes the evaporation and diffusion of water which is contained in the product, rotational movement of the turntable, electromagnetic changes of frequency and phase-shift at the ports. The modules that have been used to implement the process are RF Module, CAD import Module, and, other physics interfaces like PDE interface (to implement rotation and evaporation/diffusion) and heat transfer. The results show that power is mostly absorbed by the parts of food which are closer to the rim, and thus, drying is faster at the border. By increasing the number of degrees of freedom in terms of generated electromagnetic patterns, it is possible to facilitate the dissipation of heat even in central zone of the processed food.

Herunterladen

- bianchi_presentation.pdf - 3.42MB

- bianchi_poster.pdf - 1.3MB

- bianchi_paper.pdf - 0.86MB

- bianchi_abstract.pdf - 0.01MB