Induction Heating Optimizing for Steel Billets: Advanced Electromagnetic -Thermal Modeling Approach

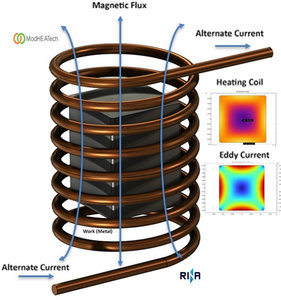

In the frame of the decarbonization of steel industry, with the aim of creating new technologies and applications, RinaCSM developed for the EU project Horizon ModHEATech an electromagnetic-thermal model with Comsol Multiphysics in order to study the heating of a steel billet by induction, before rolling mills. The activity is related to the modeling of a multiphysics process controlled in power or voltage or current.

The model was used to determine the optimal process parameters in order to respect the production and quality requirements.

An experimental investigation for induction heating was conducted to validate the model.

The thermal distribution and the current density distribution inside the billet has been studied on the basis of:

• Steelgrades • Applied supply power/current • Frequency • Initial/Final Temperature of the billet • Productivity

The study has been focused to the Reheating Furnace of SIDENOR plant, as use case; based on the simulations results, different scenario have been compared to find the best layout configuration for introduction of induction heating in the industrial site.