Femto-second Laser Texturing Prediction Using COMSOL Multiphysics®

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. In this paper, the focus is on topography prediction after ultra-short pulse laser impacts. Femto-second laser texturing offers the possibility to reduce significantly the amount of molten material. This means better surface properties as well as more accurate prediction of the surface topography.

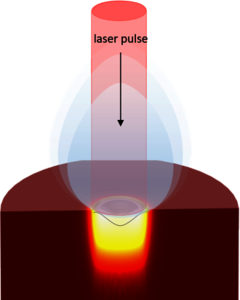

To this aim, a 2D time dependent model is developed. The energy distribution deposited on the surface by the laser is assumed Gaussian. The temperature distribution is computed in the component using the Heat Transfer module in COMSOL Multiphysics®. The ultra-short deposition of the energy is taken into account in this model through an approach called the “two-temperature model”, which consists in modelling the heating of the component through two phases. During the pulse duration, only the heating of the electrons is computed, as the timescale for continuous energy transfer is not reached. Then the heat transfer from the electron to the lattice of the material is modelled by solving the energy equation in the component. A coupling term between the temperature of the electrons and the temperature of the lattice is included to account for the heating of the lattice from the electrons energy release.

The ablation of the material is simulated using the deformed geometry option available in COMSOL Multiphysics®. The flux of ablated matter is computed using a convective heat flux under the hypothesis that the surface does not exceed significantly the vaporisation temperature. This hypothesis is discussed further in the paper. The mesh is then moved by computing the mass flux leaving the liquid-gas interface from the heat energy lost by vaporization. The material considered in this paper is AISI 316L stainless steel for its wide use in industry. The results obtained from this model are compared with existing data from literature, as well as experimental data from femto-second laser textured surfaces.