Evaluating Interfacial Evolution in Thin-Film All-Solid-State Lithium-Ion Battery via FEM Modeling

The advancement of battery technology plays a crucial role in achieving sustainable and electrified future with efficient energy storage. In recent years, all-solid-state lithium-ion batteries (ASSLIBs) have shown great potential, offering higher capacity, enhanced safety, and longer lifetime compared to batteries with liquid electrolytes [1-3]. Moreover, ASSLIBs have the capability to incorporate lithium metal, offers a high theoretical specific capacity of 3860 mAh/g as anode [4]. However, the development and commercialization of ASSLIBs are hindered by manufacturing difficulties [5] and limited understanding of the process occurring at the solid electrolyte/electrode interfaces [6-8]. These challenges arise from the complexity of the battery system and the lack of experimental techniques to investigate these processes.

The experimental evaluation of battery performance involves much trial and demands plenty of resources, time, and cost. Furthermore, it is frequently difficult to predict the properties of novel materials without extensive testing. However, predictive modelling approaches can gain insights into the complex interactions and behaviours within the battery, minimize the number of trials required and provide ideas to accelerate their realization.

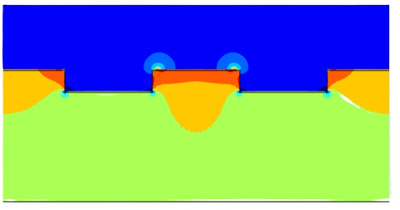

In this work, we will present our recent findings and theoretical model developments on a 2D fully coupled electrochemical-mechanical model for thin-film ASSLIBs. The model considers lithium metal as anode, Lithium Phosphorous Oxynitride (LIPON) as solid electrolyte, and a LiNi0.5Mn1.5O4 as cathode and is implemented through the finite element method (FEM) using the COMSOL Multiphysics® software. This model incorporates electrolyte mass transport, mass transport of lithium in the cathode, and stress-strain formulation defined using tertiary current distribution interface, transport of diluted species interface, and solid mechanics respectively from electrochemistry, chemical reaction engineering and structural mechanics modules. In addition to nonporous electrode reactions, homogeneous reactions in the solid electrolyte are defined. The model is validated with experimental/literature data.

The model provides valuable insights into the performance and behaviour of thin-film ASSLIBs. The simulation results (Figure 1) revealed that the highest mechanical stress is found at/near the edges/corners of the patterned geometry, electrode/solid electrolyte interface, due to the sharp change in geometry indicating a higher risk of mechanical failure. This finding suggests that the mechanical performance of the patterned thin-film structure is strongly influenced by the design of the electrode/solid electrolyte interface. Our investigation also included analyzing the concentration profile, state of (dis)charge profile, and the influence of various electrochemical/mechanical parameters under different operating conditions.

In summary, our developed model offers new insights into the behavior of patterned thin-film ASSLIBs, enabling us to optimized ASSLIBs design and operation for enhanced performance. In this presentation, we will share some of the interesting results achieved through the utilization of using this model.

Herunterladen

- Gebgregeorgis_5151_poster.pdf - 0.41MB