Electromagnetic and thermal simulation of an induction heating process for a moving thin layer strip

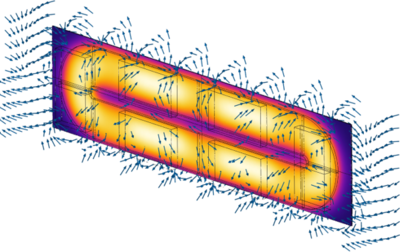

This paper focuses on the transition from gas heating to induction heating in industrial packaging processes. The aim of the study is to simulate and size the induction heating system of a thin aluminum strip for industrial welding packgies, using COMSOL Multiphysics. The strip that will be heated, is set in motion by wheels and pulleys, and the induction system consists of a couple of pancake-type coils facing the strip. Since the model is time consuming, efforts were made to simplify and decouple it to find a fast and reliable solution. The first step consists in decoupling the problem in a thermal and an electromagnetic ones. The thermal problem is solved using the "Heat Transfer " module and its features to simulate the strip movement, taking into account the system losses. Once the target power is determined, two inductors are sized to transfer the power needed to the strip. This step is performed with the "ACDC" module, using frequency studies ("Frequency Domain") coupled with "Electrical Circuit (CIR)" feature to correctly size the inductors from a circuit point of view . This approach exponentially reduced the simulation time while obtaining reliable results.

Herunterladen

- zerbetto_11031_poster.pdf - 2.98MB