Die Application Gallery bietet COMSOL Multiphysics® Tutorial- und Demo-App-Dateien, die für die Bereiche Elektromagnetik, Strukturmechanik, Akustik, Strömung, Wärmetransport und Chemie relevant sind. Sie können diese Beispiele als Ausgangspunkt für Ihre eigene Simulationsarbeit verwenden, indem Sie das Tutorial-Modell oder die Demo-App-Datei und die dazugehörigen Anleitungen herunterladen.

Suchen Sie über die Schnellsuche nach Tutorials und Apps, die für Ihr Fachgebiet relevant sind. Beachten Sie, dass viele der hier vorgestellten Beispiele auch über die Application Libraries zugänglich sind, die in die COMSOL Multiphysics® Software integriert und über das Menü File verfügbar sind.

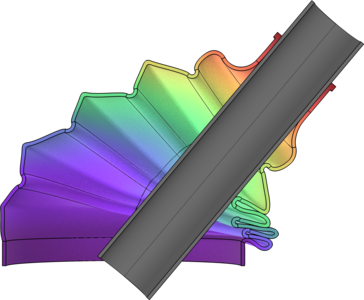

In this example, the deformation of a rubber boot seal connected to a rigid pipe is studied. As the pipe rotates and the seal deforms, the flanges of the seal self-intersect and it also come into contact with the pipe. Mehr lesen

Die forming is a widespread sheet metal forming manufacturing process. The workpiece, usually a metal sheet, is permanently reshaped around a die through plastic deformation by forming and drawing processes. Simulations can be carried out in order to avoid cracks, tears, wrinkles, too ... Mehr lesen

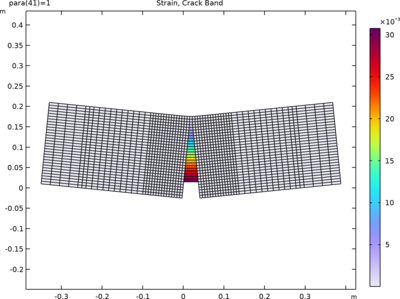

In this example, two model for brittle damage are used to evaluate the fracture of a notched concrete beam subjected to three point bending. The results are compared with experimental data. Mehr lesen

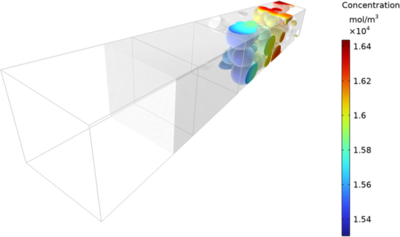

Solid-state batteries (SSB) are a promising technology that could suffer from internal mechanical stresses due to the growth and shrinkage of the electrodes within all-solid components. With this model, the charge-discharge cycling of an SSB is simulated with a focus on the interaction ... Mehr lesen

A square airbag made of a hyperelastic, compressible neo-Hookean material is inflated using pressurized air. Compressive stresses trigger wrinkling in some regions of the thin airbag. In this example, the wrinkling behavior is modeled using tension field theory, which gives a correct ... Mehr lesen

This example benchmarks a NAFEMS validation model of a friction contact problem with an elastoplastic material model. A thin metal sheet is forced into a die by a punch. Both the compressing displacement and the release of the punch are modeled in order to compute the forming angle (at ... Mehr lesen

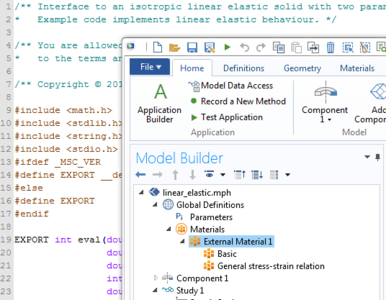

The External Material functionality makes it possible to program your own material models for cases when the built-in material models are not sufficient. For structural mechanics, you have the possibility to either completely define the material model in a domain, or to add an inelastic ... Mehr lesen

This model demonstrates the inflation of a rubber balloon with four different hyperelastic material models. The results are compared with the analytical solution for a thin-walled, spherical vessel. Controlling the inflation of hyperelastic balloons is important in clinical ... Mehr lesen

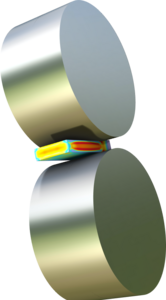

Roll forming processes are widely used in metal processing, battery electrode production and manufacturing processes. The model demonstrates the process of roll forming, where a workpiece is pressed after passing through a pair of rollers. The workpiece is carried between rollers by ... Mehr lesen

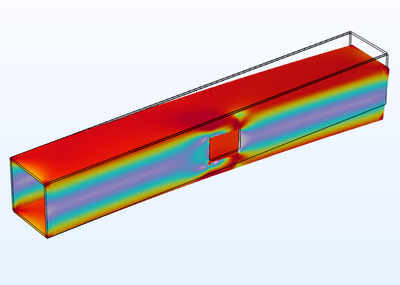

A thin-walled metal frame with a central cutout, modeled using the Shell interface, is subjected to twisting and bending. Around the cutout the stresses are higher than the yield stress, thus the material undergoes plastic deformation over the loading history. Mehr lesen