Multi-physical analysis of temperature homogeneity in vertical high temperature vacuum furnaces

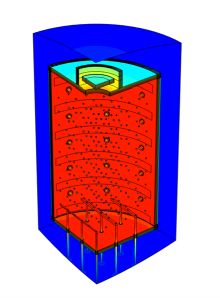

Temperature homogeneity is a critical issue for high temperature vacuum furnaces for heat treatment, as small temperature variations in the load volume can significantly influence the heat treatment result. It is generally defined by the so-called Temperature Uniformity Survey (TUS) measurement procedure described in AMS 2750. At this, depending on the size and geometry of the load volume, temperature is measured at dedicated positions with a defined number of thermocouples. In the development of refractory metal hot zones for high temperature vacuum furnaces at PLANSEE SE, multi-physical simulations are a tool for their optimization and the evaluation of the influence of new design concepts on their performance. In this contribution, a thermo-electric model is applied for a detailed analysis of the influence of different heater configurations and gas system concepts on power consumption and achievable temperature homogeneity of a vertical high temperature vacuum furnace. The 3D stationary thermo-electric model is based on the heat transfer and AC/DC module of Comsol Multiphysics. It considers electric heating, heat transfer, surface to surface radiation and convective cooling. Thin sheet structures are modelled as shells. The geometry of the furnace is built of fully parametrized parts. Symmetry in two orthogonal vertical planes is taken into account. Physics and mesh are controlled by selections. A method is used to activate physics for optional components in a parameter sweep. The current in the heaters of the heating zones is controlled by the temperature of dedicated control thermocouples using global equations. Based on the model a detailed analysis of the potential of a top and bottom heater for an improved temperature homogeneity of a vertical high temperature vacuum furnace with a cylindrical load volume with 1500 mm diameter and 1500 mm height was performed. In addition to that the potential of the “FlowBox” concept, a gas permeable multilayer structure for the top gas outlet developed at PLANSEE SE, was evaluated. At this temperature homogeneity was analysed in two different ways. Firstly, according to the TUS measurement procedure and secondly highly resolved, at positions evenly distributed along the load volume, with measurement points at the levels of and between the heating bands as well as the charge carrier rails. The simulation results demonstrate the limitations of the TUS measurement procedure for an objective evaluation of temperature homogeneity of high temperature furnaces. Cold and hot spots in the load volume cannot be reliably detected with the limited amount of measurement points. Figures 1 and 2 show the calculated temperature variations in a high temperature vacuum furnace with a TUS and a highly resolved measurement. Additional top and bottom heaters can help to reduce the cold spots induced by load carrier and top gas outlet, however at the price of an increased power consumption (see Figure 3). Comparable temperature homogeneity can be achieved with the “FlowBox” concept, without additional heaters at a reduced power consumption (see Figure 4).

Herunterladen

- leitz_28941_poster.pdf - 0.98MB

- comsolconferencepaper_final2.pdf - 1.49MB

- 1_karl-heinz_leitz.pptx - 15.42MB